Send enquiry to Advanced NDT Ltd.

ISonic PA AUT – Phased Array Flaw Detector

EngineeringIsonic PA AUT – Automatic Ultrasonic Phased Array

Product Code: ISONIC PA AUT – PHASED ARRAY

Automatic Ultrasonic Inspection of Girth Welds Combining Phased Array, TOFD, and Conventional Pulse Echo Techniques

• Up to 512 channels for connection of phased array probes

• Up to 64 channels for connection of conventional probes for pulse echo and TOFD inspection

• Parallel A/D conversion and on-the-fly digital phasing and superimposing of PA elements signals, no multiplexing involved

• Free setting of emitting and receiving aperture accumulating up to 512 elements each

• Controlled by remote PC through Ethernet, multiple units operation possible

• Easy-to-follow ray tracing, calibration, and strip chart forming wizard

• Real time strip chart recording and presentation with complete capturing of raw data A-Scans

• Ultimate ultrasonic performance for PA, conventional and TOFD probes

• Rugged IP 67 case mountable on scanner

• No need in long bulky umbilical for probes connection

• Coordinate encoder input

• Motor powering and control port

• No water or other type of cooling required

Unique cutting edge technology solution for high-speed automatic ultrasonic inspection of girth welds

In the newly constructed gas and oil off-shore and on-shore pipelines pipes are girth-welded automatically then rapidly inspected, coated, and buried. Detection, evaluation, and repair of defects in the welds must be very quick in order not to affect the construction cycle therefore high-speed automatic ultrasonic testing (AUT) of girth welds is incredibly demanded as sole codes accepted alternative to radiography AUT is implemented through scanning of weld along fusion line using several probes situated on the OD surface from both sides of girth weld. Traditionally frame with ultrasonic probes and position encoder is carried by traction unit (scanner) along orbital travel band and the umbilical connects probes, position encoder, and scanner’s motor to ultrasonic pulsing-receiving, control, data processing and recording electronics, which is placed either in the truck cabin (on-shore inspection) or in a separate room on the lay barge (off-shore inspection) at the distance of up to few tens meters from the scanning deck. A team of operators handles the AUT system: usually there are two operators involved into placement of scanning stuff onto the pipe and one operator responsible for control of scanning, observation of the indications and recording process, and taking GO/NO GO decision AUT of girth welds is regulated by couple of codes such as ASTM E-1961, API 1104, and DNV 2000 OS-F101, according to the which weld volume is divided into multiple horizontal thin slices (zones) in the cap, fill, hot pass, and root areas. Designated zones are insonified one by one through sequence of independent pulsing-receiving shots. Use of phased array (PA) technology significantly minimizes quantity of probes involved into multiple zone insonification thanks to electronic beam steering. This simplifies scanning stuff and accelerates the inspection. Use of several TOFD and conventional probes simultaneously with PA probes provides complete coverage of the weld volume at every cross-sectional position along fusion line: PA probes do implement pulse echo and tandem technique for the detection of various compact and longitudinal defects; conventional probes perform inspection for the detection of transversal defects (K- and X- schemes), detection of laminations in the heat affected zone in parent material, etc.; TOFD probes implement complimentary technology allowing detection of compact and longitudinal defects through receiving of diffracted signals. Ability of defect detection in each zone is provided through calibration of the system on specially manufactured blocks containing certain number of artificial reflectors, which’s location, orientation, shape, and dimensions represent variety of flaws to be sensed and recorded

Practical use of traditional PA AUT stuff over several years highlighted a number of inconveniences experienced by the inspection providers:

• Big expensive, heavy, bulky, and vulnerable umbilical causing relatively high operational cost as well as low signal to noise ratio and high power consumption due to transfer of analogue signals through tens meters length wires

• Insufficient quantity of A/D converters leads to use of multiplexing and elevating pulse repetition rate further increasing power consumption

• Insufficient quantity of pulsing-receiving channels requires more than one scanning revolution and / or making compromise by using the wedges of PA probes also for TOFD to inspect single girth weld completely, this slows the overall speed of AUT

• Overheat of electronics caused by high power consumption requires water-cooling or frequent shut-down breaks during work shift

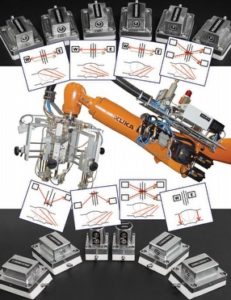

ISONIC PA AUT system from Sonotron NDT represents cutting edge technology solution for high-speed AUT of girth welds bringing practical implementation to the highest convenience level ISONIC PA AUT instrument is packed into rugged portable light weight (6.8 kg only) IP 67sealed case, which is fitted onto the scanner’s chassis; regular remote PC connected to instrument through Ethernet provides full control, data acquisition and imaging in real time, thus no big expensive, heavy vulnerable umbilical – just thin light armoured tube carries DC wires and LAN cable, which are connected to the machine through specially designed rotating terminal Probes signals are sampled and pre-processed in real time on-board; the digitised raw inspection data is transferred to remote PC for further processing, storage, and imaging. Fully digital through-Ethernet control and data transfer provide practically unlimited length of distance to remote PC enabling flexibility of creating control rooms or multiple monitor stations throughout the barge / factory / weld station, etc. Probes are connected to ISONIC PA AUT using short cables – comparing to transfer through long umbilical this provides much better signal quality significantly improving signal to noise ratio and dynamic range Further improvement of signal to noise ratio and dynamic range is achieved through firing probes with unique bi-polar square wave initial pulse reaching up to 300 Volt peak to peak for PA probes and up to 400 Volt peak to peak for the conventional and TOFD probes. Duration and amplitude for both positive and negative half-waves of the initial pulse may be tuned in wide range. Additionally it is provided high stability of firing amplitude selected by an operator while leading and falling edges of bi-polar initial pulse are electronically boosted There is no limit for quantity of PA probe elements composing emitting aperture – all elements of each PA probe connected to ISONIC PA AUT may fire simultaneously if necessary. Advanced low noise design provides the ability of up to 100 dB analogue Gain for PA, TOFD, and conventional probes ISONIC PA AUT performs 16-bit 100 MHz sampling rate digitising of signals obtained by all elements of receiving aperture at parallel independently on their quantity (aperture size) – there is no multiplexing involved; the digitised signals are phased (phase-shifted) and superimposed on-the-fly according to the desired focal law so each superimposed A-Scan is formed and memorized in the buffer in real time during the entire pulsing-receiving shot ISONIC PA AUT performs complete raw data capturing allowing play-back of all A-Scans obtained during the scanning; this provides full compliance with ASME 2235 Code Case related to use of ultrasonic inspection in lieu of radiography Rational power management eliminates heating problem; thanks to extremely low power consumption water or another type cooling is never required for ISONIC PA AUT In the ISONIC PA AUT each pulser receiver for TOFD and conventional probes may be operated in both modes – dual and single, i.e. use of dual element probes, TOFD insonification, K- and X-scheme for pitch-catch detection of transversal defects with shear waves, etc. employ only one channel per task Typically ISONIC PA AUT comprises 128 PA channels allowing simultaneous use of two 64-elements probes and 16 conventional channels, which are totally separated from PA stuff; it is easy upgradeable to 512 PA channels for future state of the art use, for example matrix PA technology allowing 3D beam steering vs today’s 2D. Quantity of conventional channels may be upgraded to 32 or 64 as well One regular PC may control and acquire data from several ISONIC PA AUT systems simultaneously (up to 16) allowing rational organization of AUT job on-site and minimizing manpower involved

Contact Advanced NDT Limited for further details and pricing.

Click here for more information on Isonic PA AUT – Automatic Ultrasonic Phased Array

Advanced NDT Ltd.

More products from Advanced NDT Ltd.

NDT Products & Equipment & Pages

Labino En-Liten White Light add on

ISonic AUT 16/32 Multi Channel Flaw Detector